How Does Resilient Seated Butterfly Valve Work?

View Larger Image

One of the most commonly used valves in the piping system. Member of the quarter-turn family, butterfly valves move in a rotatory motion. The disc of the butterfly valve is mounted onto a rotating stem. When fully open, the disc is at a 90-degree angle with regards to its actuator. This valve is suited for large flows with low pressure as well as viscous media with a large solid percentage.

Features of the butterfly valve include:

– Simple opening

– Easy to install

– Easy to maintain

– Inexpensive to install

– Requires lesser space

– Lower maintenance cost

– Suitable for larger valve applications

One way to categorize butterfly valves is based on the seat design. One such design is being a resilient seat. That being said, this article delves deeper into the mechanisms of the resilient seated butterfly valve. It also tackles the differences between the metal seated butterfly valve and the resilient seat butterfly valve.

Types of Butterfly Valves

As mentioned earlier, butterfly valves are classified in many ways. Each category works well with specific applications. Since there is more than one way to classify valves, you can customize butterfly valves depending on your preference and application.

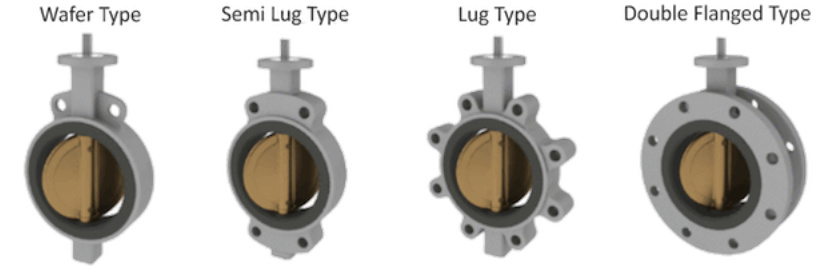

Butterfly Valves by Connection Type

This classification is based on how the valve is connected to the pipes.

Wafer Type

This is the most economical and lightweight. This design aims to prevent bi-directional differential pressures and backflows. There are two pipe flanges that sandwich the valve. They seal and connect the valve to the pipe system through bolts. For stronger sealing, there are O-rings and gaskets placed on both sides of the valve.

Lug Type

The lug type butterfly valve has lugs placed outside and around the valve body. These are often used in dead-end services or in applications that only require low pressure. The lugs are threaded. Bolts, which match that of the pipes, connect the valve to the pipe.

Butt-Welded

The butt-welded butterfly valve has the connections welded directly to the pipe. This type of valve is primarily used for high-pressure applications.

Flanged

This type is characterized by having a flange face on both sides. This is where the valves connect. This design is typical among large-sized valves.

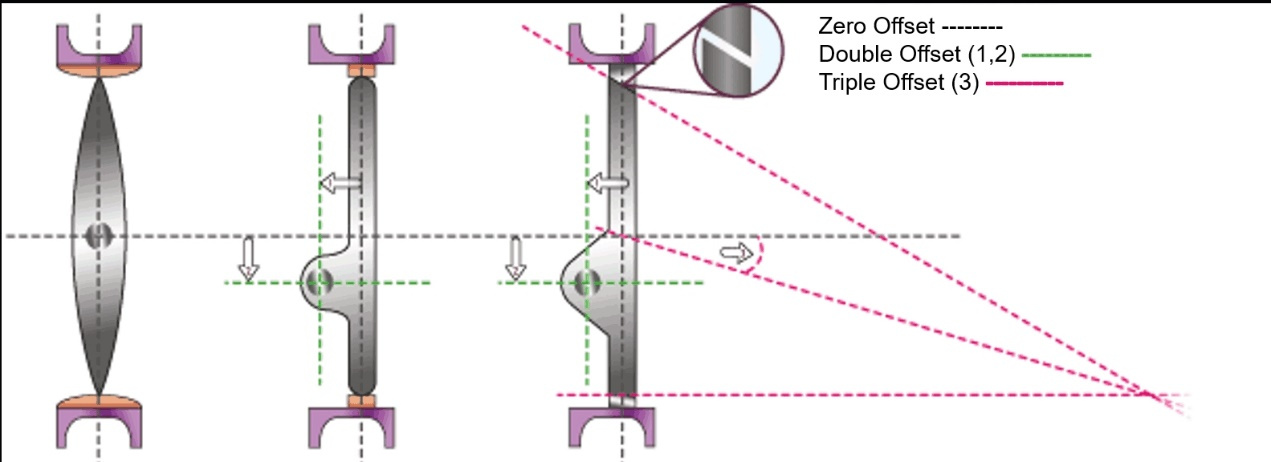

Butterfly Valves by Disc Alignment Type

This type of classification is based on the design of the seat and the angle to which the seat is attached to the disc.

Concentric

This is the most basic design among those included in this classification. This is also called the resilient-seated butterfly valve or sometimes the zero-offset butterfly valve design. The stem goes through the center of the disc and the seat. The seat is located in the internal diameter of the body. Most of the time, soft seated valves require the concentric design.

Double Offset

This is sometimes called the double eccentric butterfly valve. The disc is not aligned to the center of the body and the entire valve. This moves the seat out of the seal during operation. This mechanism lessens the impact of friction on the butterfly disc.

Triple Offset

The triple offset butterfly valve is also known as the triple eccentric butterfly valve. The seat surface creates another offset. This design ensures a frictionless movement of the disc during operation. This is common when seats are made of metal.

Butterfly Valve Function

Butterfly valves are one of those valves that can be used for both throttling and shutting on or off. It can modulate the amount or the flow of media passing through the valve at a given operation. With regards to its tight shut off mechanism, you should take into consideration the size of the line as well as the lowest required pressure drop when the valve is open.

Being a control valve, the butterfly valve needs specific calculations and allowance for media requirements and calculations such as flow requirements, pressure drops, and the likes.

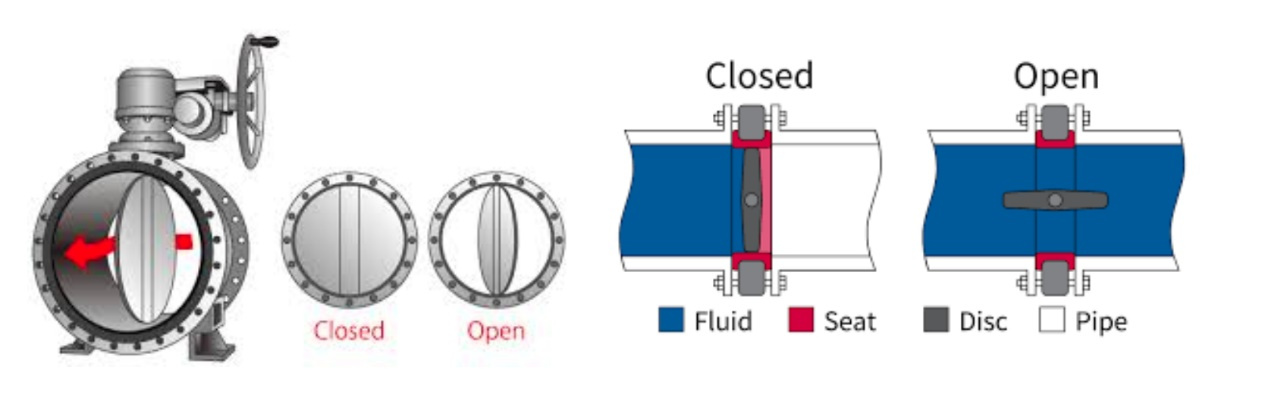

How Resilient Seated Butterfly Valve Works

A resilient seated butterfly valve is characterized by a stem that is bored into the disk and attached to the bottom of the valve. Most of the time, the seats of this kind of valve is made of rubber, hence, the term resilient.

As such, the disc relies on the high contact capability of the seat and the seat for tight shut-off. With this kind of design, the seat-to-seal contact begins at about 85-degree turn.

Resilient seated butterfly valves are made of a one-piece. This increases the strength of the valve as well as reduce its weight. The rubber-back seat makes it easy to install even when the butterfly valve is outdoors. Because of the nature of the material, it has a reliable sealing capacity.

For the seat to effectively seal, it should tightly fit and obstruct the edge of the disc. This makes the butterfly valve disc immovable. This then stops the flow. Another way of looking at it is the disc acts upon the seat which is located at the inner diameter of the valve.

Resilient Seat Butterfly Valve Material

The seats of the butterfly valve can be categorized into two. These are the soft materials and the metal-seated butterfly valve. The resilient seat butterfly valve belongs to the former. Used for non-critical applications, such butterfly seats can be made from EPDM (ethylene propylene diene terpolymer), VITON, and acrylonitrile-butadiene rubber.

Difference between Metal Seated Butterfly Valves and Resilient Seated Butterfly Valves

Resilient seated butterfly valves or the concentric ones are often soft-seated. In comparison, eccentric or the ones with the offsets, are made of metal seats, with the exception of the double offset design. This can have soft-seated material or metal. In contrast to the double offset design, the concentric valve design is cheaper.

For tight shut-off, there are always standards allowance for the metal seated butterfly valves. On the other hand, it is always zero leakage for a resilient seated butterfly valve, unless the seat is damaged.

Also, with the resilient seat design, such butterfly valves are more forgiving to a much thicker media. Regardless of the debris caught between the valve components, the seat can still provide tightness of the seal. It is also easier to replace the soft-seated seats compared to the metal seats if these are impaired. However, for the metal seat design, the seats can get stuck in position if there is debris between the internal valve components.

Resilient Seated Butterfly Valve Applications

– Cooling Water Applications

– Vacuum Services

– High-Pressure Steam and Water Applications

– Compressed Air Applications

– Pharmaceutical Services

– Chemical Services

– Oil Applications

– Wastewater Treatment

– Water Distribution Application

– Fire Protection Application

– Gas Supply Services

In Summary

Resilient seated butterfly valves are taking over the ball valves in terms of its shut off capacity. Not only are these valves simple to manufacture, but it is also cheaper to produce. With its simplicity comes the ease of maintaining, repairing and cleaning. Contact us for more details regarding XHVAL butterfly valves.