What Valves Can Be Used For Throttling?

View Larger Image

Pipeline systems are not complete without industrial valves. They come in different sizes and styles because these need to cater to different needs.

Industrial valves can be classified according to their function. There are valves stop or start the flow of media; there are those that control where the fluid flows. There are others that can vary the amount of media flowing.

Choosing the right kind of valve is crucial to an industrial operation. A wrong type would mean system shut down or system under performance.

What Are Throttling Valves

A throttling valve can open, close and regulate media flow. Throttling valves are regulator valves. Some people use the term “control valves” to mean throttling valves. The truth is, there is a distinct line defining the two. Throttling valves have discs that do not only stop or start media flow. These discs can also regulate the amount, pressure and temperature of media passing through in any position prescribed.

Throttling valves will have a higher pressure at one end and a lower pressure at the other end. This closes the valve, depending on the degree of pressure. One such example is a diaphragm valve.

On the other hand, control valves will control the flow of media with the use of an actuator. It cannot function without one.

Pressure and temperature disrupt the flow of media so control valves regulate these. Also, these valves can change the flow or pressure conditions to match the required piping system conditions.

In this sense, control valves are specialized throttling valves. That being said, control valves can throttle but not all throttling valves are control valves.

The best example is the hydraulic system where an outside force has to release the vacuum so gas can enter the valve.

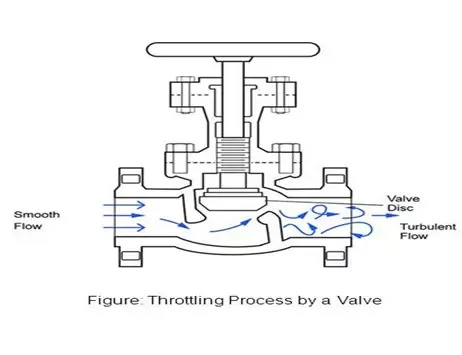

The Throttling Mechanism

When the pipeline use throttling valve, the media flow rate changes. When partially opening or closing the valve, there is a restriction in the flow of fluid. Thus, the control of media.

This, in turn, compacts the media in that partially opened valve. Molecules of the media begin to rub to each other. This creates friction. This friction additionally slows down media flow as it passes through the valve.

To better illustrate, think of the pipeline as the garden hose. Turning on, the water goes straight out the hose without any restriction. The flow is not strong. Now, think of the valve as the thumb partially covering the mouth of the hose.

The water that comes out changes in velocity and pressure because of the obstruction (the thumb). It is much stronger than the water that has not passed the valve yet. In the basic sense, this is throttling.

To apply this in the pipeline system, the system needs the cooler gas to be at the required hotter condition. With the throttling valve in place, gas temperature increases. This is due to molecules rubbing each other as they try to get out of the valve through a limited opening.

Source: https://www.quora.com/What-is-the-throttling-process

Throttling Valve Applications

There is a broad range of uses for the throttling valves. Often one can find throttling valves in the following industrial applications:

● Air conditioning systems

● Refrigeration

● Hydraulics

● Steam applications

● High-temperature applications

● Pharmaceutical applications

● Chemical applications

● Food processing applications

● Fuel oil systems

Valves That Can Be Used for Throttling

Not all valves are for throttling. Valve design is one of the major reasons why some valves are unsuitable throttlers.

Globe

Globe valves are one of the most popular kinds of valves. The globe valve is primarily used as a throttling valve. This belongs to the linear motion valve family. The globe disk moves up or down in relation to the stationary ring seat. Its disk or plug controls the amount of media that can pass through.

The space between the seat and the ring allows the globe valve to function as a great throttling valve. There is less damage to the seat and disk or plug because of its design.

Limitations

Because of the design of the globe valve, when used in high-pressure applications, it needs an automatic or powered actuator to move the stem and open the valve. Pressure drop and range of flow control are the two considerations for efficient throttling capabilities.

There is also the possibility of leakage due to damaged seat as this comes in full contact with the flow media. This valve is also prone to the effects of vibration, especially when the media is gas.

Butterfly

Butterfly valves look like the gate valve. But, one of their distinct differences is the butterfly valve belongs to the quarter-turn valve family.

An outside force acts on the actuator. This actuator is attached to the stem which connects to the disc.

Among the most common valves, the butterfly valve is the most suitable for throttling. A full quarter turn can open or close the valve. For throttling to happen, it only needs to open a bit for the media to pass.

Limitations

One of the limitations of the butterfly valves is that the disc is always in the path of the media flow. The entire disc is more susceptible to erosion. Also, because of this design, cleaning the internal parts is difficult.

For the butterfly valve to be effective, proper calculations must identify the maximum flow and pressure requirements.

Gate

The gate valve belongs to the linear motion valve family. Gate valves have discs that move up and down for the opening and closing of the valves. They are primarily used as a turn on-shut off services. Gate valves have limitations as throttling valves.

In an almost-shut aperture, throttling happens as it limits the flow of media. This increases the velocity of the media as it goes out of the valve.

Limitations

The only time that you should use gate valves for throttling is when the valve is 90% closed. Closing it to just about 50% won’t achieve the desired throttling capabilities. The downside to using the gate valve is that the velocity of the media can easily erode the face of the disc.

Additionally, gate valves should not be used as throttling valves for long durations. Pressure can tear the gate seat so the valve can no longer completely shut off. Another, if the medium is liquid, there is vibration. This vibration can also affect the seat.

Pinch

Considered as one of the simplest designs, the pinch valve has a soft elastomer liner. It is pinched to close using fluid pressure. Hence, its name. Belonging to the linear motion family, the pinch valve is lightweight and easy to maintain.

Pinch valves are very effective when sterility and sanitation are the priorities.The elastomer liner protects the metal parts of the valve.

The stem attaches to the compressor which is lined exactly above the liner. The pinch valve closes when the compressor lowers to the liner.

Throttling capabilities of the pinch valve is usually between 10% to 95% flow rate capacity. Its best efficiency rate is at 50%. This is due to the soft liner and smooth walls.

Limitations

This valve does not work best when the media has sharp particles, especially when the valve is 90% closed. This can cause tears in the elastomer liner. This valve is not suitable for gas media, and high pressure and temperature applications.

Diaphragm

The diaphragm valve is quite similar to the pinch valve. However, its throttling device is an elastomer diaphragm instead of an elastomer liner. You can check how diaphragm valves work in this video.

In the pinch valve, the compressor lowers into the liner and then pinches it to stop the media flow. In the diaphragm valve, a diaphragm disk presses against the bottom of the valve to close it.

Such a design allows larger particles to move through the valve. Between the straight through diaphragm valve and the weir type diaphragm valve, the latter is better for throttling.

Limitations

Although it can provide a non-leak proof seal, diaphragm valves can only withstand moderate temperature and pressure range. Additionally, it cannot be used in multi-turn operations.

Needle

The needle valve is similar to globe valves. Instead of a globe-like disk, the needle valve has a needle-like disk. This is more suitable for applications that need precise regulation.

Additionally, needle valves are better valve control regulators for smaller quantities. The fluid goes in a straight line but turns 900 if the valve is opening. Because of that 900 design, some parts of the disk passes through the seat opening before a complete close. You can view the pinch valve 3D animation here.

Limitations

The needle valves are for delicate industrial applications. That being said, thicker and viscous media are unsuitable for needle valves. The opening of this valve is small and particles in slurries become trapped in the cavity.

How to Choose Throttling Valve

Each type of throttling valve has its advantages and limitations. Understanding the purpose of implementing throttling valve always narrows down the choices for the right kind of throttling valve.

Valve Size

The right valve size means doing away with future valve issues. For example, a valve too large means limited throttling capacity. Most probably, it would be near its closed position. This makes the valve more prone to vibrations and erosion.

Furthermore, the valve that is too big would have additional fittings as an adjustment to the pipes. The fittings are costly.

Material of Construction

The valve body material is an important aspect when choosing the throttling valve. It should be compatible with the type of material that would pass through. For example, chemical-based media should pass through a non-corrosive valve. Media that tends to reach high temperature or pressure should pass into a strong alloy with internal coating.

Actuation

Actuation also plays a big role in choosing the right throttling valve. In pipeline applications, there are instances that strong pressure is present. A manual actuator may not be efficient in opening or closing the valve because of that.

Connections

How the valve is connected to the pipes is also worth considering. It is important to adapt to the existing pipe connections rather than the pipes adapting to the valve.

It is more cost effective to suit the valve to the existing pipe requirements. For instance, when the pipe ends have flanges, the valve should also have flanged end connections.

Industry Standards

Industry standards are just as important. There are standards for the type of material to use for a particular media. There are also standards on end connections or the thickness of the metal to use for the valve.

Such standards bring safety to applications. There is often an increase in temperature and pressure when using throttling valves. By that, it is vital to understand such standards for the safety of everyone.

In Summary

While most valves have limited throttling capabilities, one does not simply use them as so. For the valve to last longer, it is best to know what type of valve is suitable for a particular throttling application.

Reference valve manufacturer resource: The Ultimate Guide: Best Valve Manufacturers in China